Miranov sees bioprinting as Art. You can see this take from his own university homepage:

http://www.musc.edu/bioprinting/html/bioprinting_art.html

here he talks about the importance of looking at bioprinting as an art, as a technology that will change the way humans think and perceive life. This has sparked much conversation between the public and arguments about morality and ethical treatments of humans. These can be seen on another blog:

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-social-and-cultural.html

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-response-continued-on-social.html

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-response-to-thacker.html

Chapters

Miranov's bioprinting art

Miranov's Debacle

Miranov is one of the two leading scientists in the field of bioprinting. He holds this technology as the "most important invention since the printing press", and does not just see the technology as a way to build organs for therapy. He has tried to get grants for printing protein for NASA

http://www.futurepundit.com/archives/000846.html

this article is about his grant that was turned down. He saw a potential for printing steaks for NASA astronauts to take up into space for true protein sources. From there he also thought about the use of printing steaks from human tissue for vegans, "that would allow [them] to eat meat without feeling that [they have] killed an animal". A very interesting idea, and a very interesting moral dilemna for society. Can we see a future in which cannibalism is embraced? Evolutionarily, our genes have caused us to always have an aversion to people that would eat their own (seeing as it would affect survival directly), so have we finally found technology that would make it harmless!?

Miranov is very creative and is insistent on how the bioprinting technology can be used for every aspect of life. Let's hope some are taken into account and others are left to philosophy.

Laws & Regulations

To date the FDA is closely reviewing many of the cloning and gene therapy processes to make sure it regulates what needs to be regulated. Though there are laws against using fetal stem cells, as well as human cloning regulations; there are not any laws against the use of iPS technology nor the cloning of parts of humans (organs).

The FDA website on cellular & gene therapy is http://www.fda.gov/cber/gene.htm

It is important to look at the laws and regulations before any public opinions, since laws change public opinions and vice versa.

How it Got Started

A video from Discovery Channel is what sparked my interest in the topic. That interest was continually sparked in a class titled: Genes, Genethics, and Public Opinion, in which we studied technology and science that is happening as we speak! The further investigation of the possibility of this future was surprising, and it made it necessary for me to share. In order to fully understand the possibility of personalized organ printing, one must understand:

- the production of stem cells, in all there forms

- What is needed to make an organ

- How a conventional printer can be changed for biological purposes

- How 3D printing is possible

- How laws & public opinion will shape the progress of this future innovation

and finally

2057: The Body

Yes, here it is, the video the placed the spark: 2057 - the body. The important time interval is from 00:50 to 07:40 .

Newspapers, Associations

Dr. Wei Sun & bioprinting http://www.wilsonpost.com/index.php?option=com_content&task=view&id=82&Itemid=2

Regenerative med article

http://www.futuremedicine.com/doi/abs/10.2217/17460751.3.1.93

CBS (bioprinting symposium)

http://www.charlestonbusiness.com/pub/12_18/news/7388-1.html

New scientist bioprinting Mironov SCAFFOLD TECHNOLOGY

http://www.newscientist.com/article/dn3292-inkjet-printing-creates-tubes-of-living-tissue.html

public opinion with miranov:

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-response-to-thacker.html

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-response-continued-on-social.html

http://visualcultureandbioscience.blogspot.com/2007/03/mironov-social-and-cultural.html

http://www.futurepundit.com/archives/000846.html

http://www.musc.edu/bioprinting/html/bioprinting_art.html

ASAIO (american Society for Artificial Internal Organs)

www.asaio.com

Paper Sources

Flanagan, T. C., Cornelissen, C., Koch, S., Tschoeke, B., Sachweh, J. S., Schmitz-Rode, T., et al. (2007). The in vitro development of autologous fibrin-based tissue-engineered heart valves through optimised dynamic conditioning. Biomaterials, 28(23), 3388-3397.

Mironov, V., Boland, T., Trusk, T., Forgacs, G., & Markwald, R. R. (2003). Organ printing: Computer-aided jet-based 3D tissue engineering. Trends in Biotechnology, 21(4), 157-161.

Trounson, A., & Elefanty, A. (2007). Stem cells in biology, tissue engineering and medicine: The leading edge keeps moving. Current Opinion in Biotechnology, 18(5), 432-433.

Xu, T., Jin, J., Gregory, C., Hickman, J. J., & Boland, T. (2005). Inkjet printing of viable mammalian cells. Biomaterials, 26(1), 93-99.

Xu, T., Petridou, S., Lee, E. H., Roth, E. A., Vyavahare, N. R., Hickman, J. J., et al. (2004). Construction of high-density bacterial colony arrays and patterns by the ink-jet method. Biotechnology and Bioengineering, 85(1), 29-33.

Stem Cells & Bioengineering

Any time an organ is engineered, have it be skin, a heart, or a pair of lungs; the way it is made is not by laying down mature differentiated cells. This is because it would cause many problems in a full organ: the cells would not attach with eachother, they would not cooperate with eachother, and they would be worn already (meaning their life expectancy is severely lowered). It is necessary to use stem cells, or pleuripotent cells that will mature into the form that they are processed in.

The types of stem cells that are used in bioengineering are reviewed in a very eloquent paper by Trounson titled: Stem cells in biology, tissue engineering and medicine:

the leading edge keeps moving.

The paper discusses how each type is allowing the progression of bioengineering, and medecine. Induced Plueripotent Stem cells (iPS) are discussed as a great way to turn any mature cell back into a stem cell, which allows for personalized stem cells to be made out of any cell in our body. We could effectively take a cheek swab and grow a kidney! This is the power of iPS, and happens to be the most useful way to engineer something that will be "exactly what the doctor ordered". Imagine having a heart that is exactly like your heart, from your cheek cells! The thought is mind-blowing, but the possibility is there.

3 Methods to Bioengineering

Bioprinting is not the only way to manufacture an organ. Bioprinting may not even be the best way, however it is starting to seem that way due to its speed, ease of use, and accuracy. The results are equal to other methods, and the technology may allow for a bettering of those results.

the 3 Methods:

1. Host Growth- This method uses stem cells which are transplanted into another organism. The organism acts as a host to the cells while they grow and mature, and then the organ is removed. Mini human kidneys were grown inside a mouse using this technique, though I don't know who would need mini kidneys! The results is a properly functioning organ, however it takes many months to grow.

2. Layer-by-layer placement- unlike printing, this method places each cell one layer at a time. It must allow each layer to grow on its own before combination of layers are attached. Also a timely process.

3. bioprinting- This is the method that will be discussed thoroughly. It uses modern day ink-jet printers, modified to lay down cells. These cells are then grown in a gel scaffold and the result is a fully formed organ, true to size, and within a couple weeks.

Printing: An Explanatary Video

This video is a great representation of what you can expect biprinting to become. The whole video was done by the Boland research team at Clemson using CAD (computer Aided Drawing). I would recommend watching it without sound; there is no commentary and the music is quite distracting, though humorous.

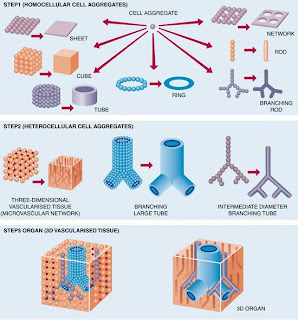

for more information on how complex organs can be printed, this figure tries to explain how a printer can place different types of cells in different arrangement to form a complex system.

Scaffolds: Holding an Organ Together

In bioengineering it is important to have the ingredients to grow an organ, the correct environment for which those ingredients to grow, and of course a blueprint for them to grow on. Scaffolds have always been a hard obstacle to overcome due to the necessity of them to disappear after the growth has ceased. There have been many advances in that field: organic structures that will decay, and easily removable structures that act as molds for growth. Both of these are viable options, and both provide a different way of building organic structures. However when using a printer it is difficult to place a scaffold layer-by-layer, let alone have the printer lay cells out around an obstruction. Luckily, researchers have come up with a brilliant gel that will act as a place holder for the cells and tissues as they grow. Miranov et al. managed to produce a reverse-thermal gel that allows the printer to place cells whereever it is supposed to and have a gel wash over it before and after. This gel hardens immediately, rooting those cells in place and providing nutrients for them to grow, align, and attach.

As you can see this process is much easier for a printer to achieve, and is the basis of scaffolding in bioprinting. The gel is solid at 37 degrees celsius, but becomes a liquid at 20 degrees celsius; therefore once growth is complete, the gel can simply be cooled and removed through dripping.

This, in a nutshell is the future of bioprinting scaffolds, and is going to form the basis of many other technologies.

Source: http://www.newscientist.com/article/dn3292-inkjet-printing-creates-tubes-of-living-tissue.html

Jockenhovel: Conditioning a Bioengineered Organ

Taking a quick departure from cell printing, it may be useful at looking at how far bioengineering has come in all methods. Jokenhovel et al. engineered a heart valve using specialized cell tissue. The result was an autologous fibrin-based heart valve complete with extracellular matrix. The question that had to be answered though is what method of conditioning was best to ensure cell alignment, attachment, and strengthening. It is important in all bioengineering that the end result be true to the actual structure in the body; therefore, a heart valve should not just look like a heart valve, but work like one for as long as the natural one as well. Jockenhovel et al. placed their scaffold and cells in a bioreactor under three conditions: dynamic conditioning (slowly increasing BPM), optimized dynamic conditioning (BPM changes randomly between 5BPM, 10BPM, and 15BPM), and the control is stirred (where bioreactor materials are continually circulated).

The image above is the bioreactor used, and displays the exact set-up. The ability to change BPM, and partial pressures of Oxygen and Carbon Dioxide is also shown. This an important measure to take because organs must be conditioned under the same environment that they will be working in.

After running 12 day bioreactions under every condition, what was found was that optimized dynamic conditioning allowed for the strongest cell alignment and attachment.

The figure above shows three cell histologies, all including one of the valve flap (leaflet) and one of the valve wall. What is shown is that native valves have blue collagen ECM that allows it to stay attached and strong through pumps. The control valve does not have these markings of collagen, and also has major tears that display no alignment or attachment of cells. The dynamic conditioned valve, however, has an abundant amount of ECM collagen and seems to be even stronger than the native valve. This dense population of cells and ECM seems to support the practice of exercising an organ in a rigorous environment, equal to its native environment.

This study is important because it focuses on the necessity of conditioning a bioengineered organ. This will come in handy for organ printing because after an organ is printed it must be conditioned to work true to nature. In other words, a clump of cells arranged in the shape of a heart is not enough to be a heart, the scientists must also figure out how to best condition the heart to be as strong (or stronger) than the heart it will be replacing.

Thomas Boland: on the Leading Edge of Bioprinting

Boland is one of the leading researchers into printing cells using modified ink-jet printers; Miranov is the other main figure head in this area. There are three sequential papers that show the thought process and success that has been had

The first discusses the possibility of using a modified ink-jet printer to print cells. The question was whether it would be feasible to print organs, and started by using clumps of cells and watching for two things: proper cell attachment and alignment. Using Computer-aided Drawing techniques Boland et al. showed how it would be possible to use cell printers to build up layer-by-layer an entire organ.

The figure to the left shows both a technical drawing and an actual view of the first endeavor into cell printing. What was done was a simple circle of cell clumps. The purpose was to find cell alignment boundaries, how far a cell must be from another in order for proper alignment to occur. What is great is that, what was hypothesized through CAD is in fact what happened in actuality. Success!

The next two images are CAD renderings of how a 3D structure could be built layer-by-layer, given different types of cells and different structures (tubes and branchings). The second image is a rendering of what a cell printer today can expect to look like, but in the future it would have to be larger and have more possible cartridges.

The second paper, after the first paper’s success, set out to see if the actual printer could print bacteria cells exactly where the they wanted. Two questions must be answered before they move forward: can bacterial cells be printed exactly where they are, and will they grow. Using a direct approach, Boland et al. printed bacteria cells onto a thin glass agar plate into the “Clemson *paw*” design seen below. The results were wonderful, the bacterial cells were placed in the right alignment, and they began to grow.

The third paper takes one of the final steps, which is using mammalian cells to find out if printed cells will align, attach, and grow successfully. Using a HP ink-jet printer, Boland et al. decided to use Chinese Hamster Ovarian (CHO) cells that were transfected with green fluorescence, and primary embryonic motoneuron cells. These cells were then printed onto bio paper and placed in an incubator. Viability along with alignment and attachment was found by measuring LDH levels, an enzyme that is released from lysed cells. An increase of LDH means less surviving cells, and therefore shows a defect in the printing process. The table below shows the results of cell printing and viability. It shows the success of printing mammalian cells, since the lysing levels were extremely low and those lysed caused by the printing process is lower than those caused by bio-ink formation. This is a good sign because a formulation can be changed until it cause less lysing, but the printing process has little available change. The next important question is whether the amount that are always going to lyse, is critical for proper organ functioning.

The figure below shows the fluorescent ovarian cells, and it is important to note the alignment and attachment of cell clumps.

These three papers have all shown promise and success. Boland et al. began with a complex idea that was tested over and over again. They now can print mammalian cells that are viable, and align in the proper spots. They have also solved the scaffolding problem by method of reverse-thermal gels, except that the formula is causing some mammalian cells to lyse. After this is cleared up, if it can be, viable organs should not be too far behind!

Bringing It All Together

From these papers it is clear that organ printing is a viable option for bioengineering. It also is making leaps and bounds in its improvements: in three years it went from being a CAD (computer aided design) to being an actual printer that will print 3D layers of tissue and within those layers over 99.9% stay viable, attached, and aligned. The revolutionary reverse-thermal gel allows the printer to only worry about where it places cells, not where a scaffold is. This allows the possibility of any design to be made easily without worry of first figuring out the scaffold design!

A note of caution though: an clump of cells that look like an organ does not an organ make. As seen through Jockenhovel's paper, simply bioengineering layers of tissues does not mean that it will be a strong and long-lasting option. After the organ is printed it must be put through some conditioning in order to build the muscle, and allow proper cell cooperation. In any organ, especially a heart, this is imperative to functioning.

The power of organ printing lies in its speed, accuracy, and its ability to take any cell, be it a ovary cell, an iPS cell, or ECM; and make a personalized organ. Soon this technology will allow every one of us, with proper insurance, to give a doctor our own cells and get back a fully functional liver, kidney, heart, lung, or skin. This has the power to be one of the most revolutionary inventions since the printing press!